A New Era of Cooling

While liquid cooling and natural refrigerant heat rejection systems have been around for years, combining these technologies for data center cooling is a game-changer. Traditional synthetic refrigerants have dominated the space until now, but the increased loads and demand for more efficient systems call for a new approach.

CIMCO’s natural refrigerant liquid cooling solution is designed to handle the heat loads of high-density data centers while offering:

- Lower energy consumption

- Reduced operational costs (OPEX)

- Ease of service and simple maintenance cycles

- Scalability for future growth

Built for Your Data Center

With over a century of experience in thermal solutions, CIMCO has been at the forefront of innovation since 1913. Our cross-sector expertise and deep engineering knowledge allow us to design systems tailored to your specific needs — because when it comes to high-performance data centers, a one-size-fits-all solution just doesn’t cut it.

As the industry continues to evolve post-2024, every data center’s needs are unique. Off-the-shelf products fall short of meeting those demands. That’s why we take the time to understand your challenges and goals, working closely with you to deliver a liquid immersion cooling solution designed to fit your infrastructure and performance requirements.

Unlike conventional chillers, our systems are designed for whatever temperature and flow requirements that you want.

Our Approach

We collaborate with you to:

- Evaluate space and infrastructure: Ensure your facility is ready to implement liquid cooling efficiently.

- Seamlessly integrate new systems: Design solutions compatible with your existing infrastructure for smooth retrofits into legacy facilities.

- Optimize operational considerations: Plan for daily functionality, ensuring your cooling system supports uninterrupted performance.

Customers We Proudly Serve

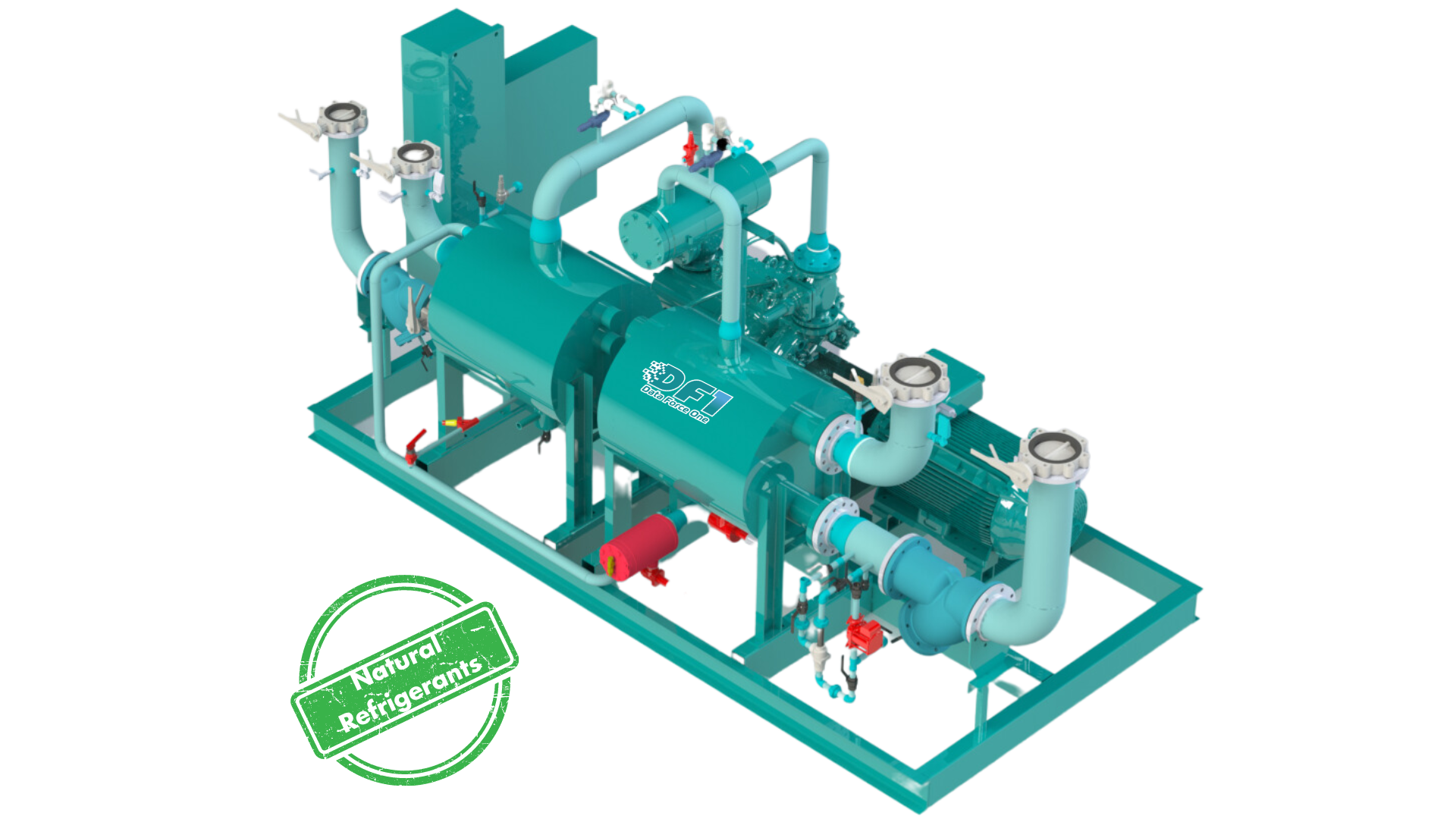

Our Foundational Solution: Data Force One

For data centers looking for a proven, high-performance cooling system, CIMCO’s Data Force One is the perfect starting point. Designed specifically for data center environments, Data Force One delivers reliable cooling for a wide range of workloads — all while prioritizing energy efficiency and sustainability.

A customized, robust natural refrigerant system made for data centers

Low-Charge Ammonia:

Well-known refrigerant with proven favorable thermodynamic properties and lowest direct emissions possible (GWP = 0 | ODP = 0)

Heavy-Duty Compressors:

Industrial-grade parts designed for efficiency, versatility, serviceability, and safety.

Heat Recovery:

The ability to recover waste heat for use in other areas of the facility, reducing overall energy consumption.

N+1 Redundancy:

Allows for one extra component (compressor, pump, etc.) beyond the required capacity, ensuring reliability in critical applications.

Customized Automation:

Measuring, monitoring, and controlling the facility’s equipment to maximize performance and efficiency.

.png?sfvrsn=5255d922_0)

Automatic Refrigerant Pump-Out:

Automatically senses and contains refrigerant leaks. (With optional Smart Transfer)

Thermal Storage Compatibility:

Connect heating and/ or cooling storage to reduce peak demand energy consumption and related costs.

Wide Operating Range:

Designed to operate efficiently in a broad range of ambient temperatures, ensuring consistent performance year-round.

Related Posts

Industrial Heat Pumps are the Past, Present and Future

Interconnected Efficiency: Leveraging Ammonia Heat Pumps for Sustainable Manufacturing