NET ZERO NATURALLY

What does it take to get there by 2050? Hint: Your refrigeration system is just the start.

A natural or non-synthetic refrigerant, like Ammonia and CO2, can be found in nature. A synthetic refrigerant is human made. Examples of synthetic refrigerants are chlorofluorocarbons (CFCs), hydrofluorocarbons (HFCs), and hydrochlorofluorocarbons (HCFCs). These synthetic refrigerants are members of the fluorinated gas (F-gas) family, many of which have been phased out (no longer produced) or phased down (production is winding down) because of government regulations based on environmental concerns.

The science around climate change says that natural refrigerants like Ammonia and CO2 are environmentally-friendly choices for right now, and for the future. We couldn’t agree more. In fact, in early 2021, we announced that we no longer manufacture ice rink packages using HFC-based refrigerants such as Hydrofluoroolefin blends (HFOs).

The international focus on sustainability, climate change, and environmental preservation has led to a renewed global interest in natural refrigerants because they have the potential to improve the environmental performance of refrigeration systems. CIMCO is proud to be a part of this change, and it’s why in early 2021, we stopped manufacturing ice rink packages using synthetic refrigerants such as Hydrofluoroolefin blends (HFOs)

As the name suggests, natural refrigerants are found naturally in the environment and include ammonia, carbon dioxide, hydrocarbons, water, and air. Since they occur naturally, they are an environmentally-friendly choice and are suitable for multiple applications in refrigeration and air conditioning systems. These refrigerants have been used for decades, and following the Montreal and Kyoto protocols and concerns over environmental sustainability, there is a renewed global interest in them.

Compared to human-made synthetic refrigerants like chlorofluorocarbons (CFCs), hydrofluorocarbons (HFCs), and hydrochlorofluorocarbons (HCFCs), natural refrigerants do not harm the environment, have negligible to very low Global Warming Potential (GWP), zero Ozone Depleting Potential (ODP), and do not contribute to greenhouse gas emissions.

On the contrary, synthetic refrigerants are members of the fluorinated gas (F-gas) family, many of which have been phased out or phased down because of government regulations based on environmental concerns and adverse effects on living things. The degradation of fluorinated refrigerants also results in the formation of trifluoroacetic acid (TFA), a highly soluble chemical that persists in the environment and accumulates in lakes, water reservoirs, and wetlands. It comes down to the ground as acid rain and cannot be treated with the current water treatment plants. This chemical has a detrimental effect on humans, aquatic animals, and the environment.

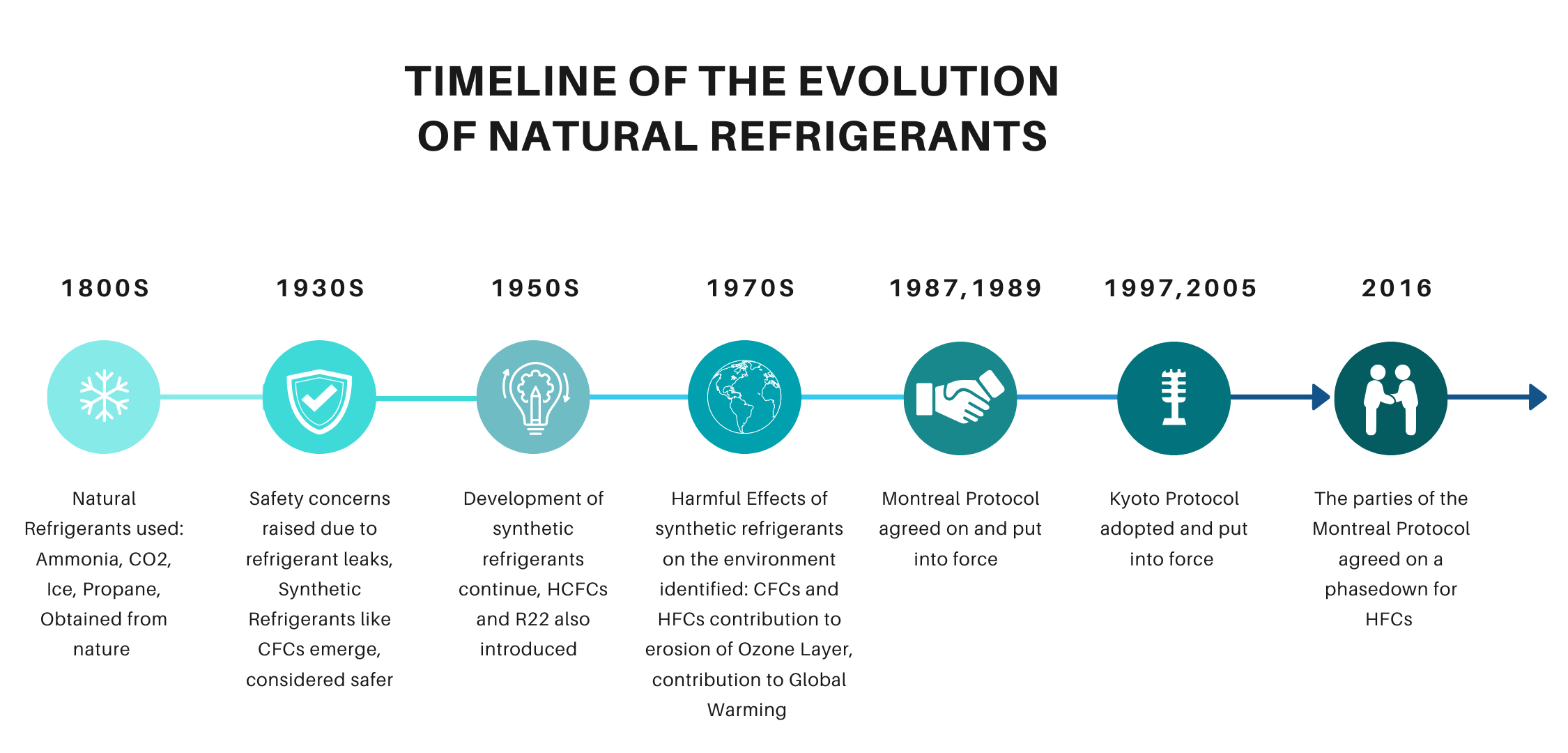

The history of natural refrigerants goes back to the 18th century when all refrigerants existed in nature. Some of these, like ice, were obtained from sources such as local ponds and rivers to be used for industrial applications. Ammonia and CO2 were popular at that time as refrigerants. By the 1930s owing to the rise in leakage issues and safety challenges with early refrigerants, CFCs— the first generation of synthetic refrigerants—were invented, and at that time were considered to be safer alternatives. The development and use of synthetic refrigerants kept increasing in the 1950s when R22 (also known as Freon) was introduced. It was only in the early 1970s that the CFC refrigerants' detrimental effect on the ozone layer was discovered. Reacting to this, the Montreal Protocol, an international treaty, was agreed on in September 1987 and put into force in January 1989. Later HFCs began to be used as substitute refrigerants. While their ODP might be lesser than their predecessors, HFCs have medium to high GWP and hence in October 2016, the parties of the Montreal Protocol agreed on a phasedown for HFCs. Hence a renewed global interest in sustainability and environmental protection has brought back attention to natural refrigerants as viable and future-ready refrigeration options.

This is the metric that compares the global warming impacts and of different greenhouse gases, the gases in the Earth’s atmosphere that trap heat. Each GHG has a unique atmospheric lifetime and heat-trapping potential, and its GWP is calculated compared to CO2, which has a GWP of one. For example, if a refrigerant gas has a GWP of 600, that means it has 600x the environmental impact of CO2.

The ODP of a refrigerant gas is the relative amount of degradation it can cause to the ozone layer.

Ammonia (R-717):

Ammonia is among the oldest refrigerants, and is an environmentally friendly natural refrigerant with an ODP and GWP of zero, and has a wide range of applications in multiple industries. It offers optimum cooling across a range of temperatures and applications, and low-charge ammonia utilizes lesser volume compared to other refrigerants. Choosing ammonia as a refrigerant for your system would bring optimum energy efficiency, heat recovery, and reliability. It is easy to detect any leaks in the system due to its pungent smell, as well as the installation of sensors, thus ensuring enhanced safety.

.png?sfvrsn=a3fdc022_0)

Carbon dioxide (R-744):

The use of CO2 as a refrigerant has seen many ups and downs, but it has gained worldwide interest once again owing to its efficiency and reliability. It has an ODP of zero, a GWP of one, is non-flammable, has a low toxicity, and is being used as a refrigerant in multiple industrial, commercial and recreational applications. Because of its high pressure/temperature characteristic, CO2 offers high gas density which equals a greater refrigerant effect when compared to other refrigerants from a given compressor and very small reductions in saturation temperature for a given pressure drop. This is why the refrigerant delivers excellent performance at low temperatures.

.png?sfvrsn=b23bc322_2)

Other natural refrigerants:

The other natural refrigerants include hydrocarbons, water, air and some of its constituents in niche industrial applications. Oil and natural gas fall under the category of hydrocarbon refrigerants. Hydrocarbons most commonly used as refrigerants are methane, ethane, propane, butane, isobutane, ethylene, and propylene.

Choosing a natural refrigerant for your facility-be it an industrial unit or an ice rink- will come with multiple advantages, including higher efficiency, productivity, reliability, and sustainability. The quality of the ice at your rink will be unparalleled which will translate to a rich skating experience for the skaters. Additionally, a natural refrigerant will aid you on the path to net-zero by reducing your carbon footprint and offering heat recovery. Over the years, these refrigerants have become the preferred choice in multiple industrial applications, from food processing and pharmaceuticals to mining and manufacturing.

What does it take to get there by 2050? Hint: Your refrigeration system is just the start.

From installing an HVAC system for a mass COVID-19 vaccine centre to keeping ice pristine at an NHL training facility—and everything in between.

We separate fact from fiction, and dispel some of the myths about naturals and synthetics.

Whether you want to build a brand new net-zero facility, or you're updating an existing arena to avoid the phase outs of HFC-based synthetic refrigerants, we have the refrigeration products and expertise to make it all happen, with technology that’s customizable, cost-effective and built to last.

.png?sfvrsn=40fec022_0)

Advancement in technology and connectivity gives us a deeper understanding of product function to improve performance and output. CIMCO provides you with a suite of smart tools and expertise you need to reach net-zero emissions.

.png?sfvrsn=8b3bc322_2)

Advancement in technology and connectivity gives us a deeper understanding of product function to improve and maximize performance and output. CIMCO provides you with a suite of.

Learn more

-(15).png?sfvrsn=cf17c322_3)