We compiled some frequently asked questions on using CO2 refrigeration systems (with a particular look at how they compare to ammonia systems)

CO2, or R-744, is a natural, non-toxic, and non-flammable refrigerant with no net greenhouse gas effects. It provides the optimum balance of performance, efficiency and safety, ideal for both new installations and retrofits of existing systems.

As a natural substance with minimal impact on the environment, it is unlikely to be phased out (which can be quite a costly endeavor). It is non-corrosive with most materials, and a good option for R-22 (Freon) replacements.

We never tire of recommending CO2 as a consideration for your next refrigeration system. However, we realize that there are many questions concerning this refrigerant that go unanswered. While we strongly recommend contacting us directly for any specific queries, we thought we would compile a series of questions we have recently received about CO2. Hope this helps clear up some of the common doubts!

CO2 Vs. Ammonia

How is the day-to-day operation of a CO2 system similar to or different from an ammonia system? (For example: draining/adding oil, condenser/cooling tower maintenance and sanitization, etc.)

The outdoor condenser is, in fact, a gas cooler. In transcritical mode, the gas is no longer condensing but cooling down from a high temperature to a lower temperature. Since it could be done with a dry or adiabatic gas cooler, the usage of water is no longer required, or a slight amount for extreme warm outdoor conditions. This eliminates the water treatment system of a cooling tower and tremendously reduces water waste and usage.

How does the life span of a CO2 system compare to an ammonia system?

The life span is very similar. All components are replaceable without requiring major renovation. Compressors are low-cost unitary equipment (vs overhauls), and multiple glycol chillers can be replaced. All of the piping is stainless steel, so no rust and insulation would be Armaflex covered with PVC.

How often will CO2 need to be charged to the system? What would this cost (compared to ammonia)?

CO2 would never need to be charged to the system unless service requires the system to be emptied for a major repair (which is an unlikely scenario). In case of a leak, the charge for a 160 TR system would be around 500 lbs. The price of CO2 is between $2-$3 per pound.”

In an indirect CO2 system, is the glycol/brine system the same as would be used for an indirect ammonia system (header trench, under ice piping, etc.)?

In other words, if we were to install a CO2/glycol indirect system today, and decide in the future to replace the system with an ammonia/glycol indirect system, can the underfloor glycol piping remain as is? Could we just disconnect the CO2 system and swap it out with an ammonia system? Absolutely. The glycol circuits would not be affected and would have no impact. In fact, the cooling tower supplied as the condenser in an R6 plant could remain and be used with an ammonia package replacement.

Since CO2 is not self-alarming, what extra safety measures are needed?

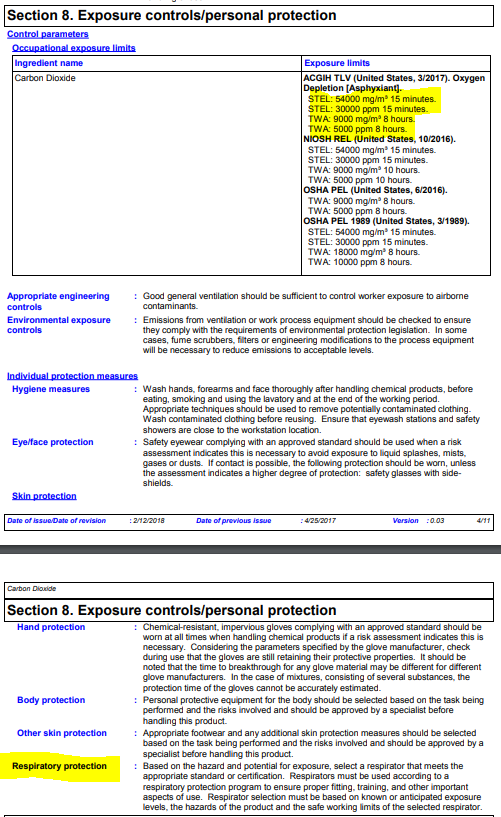

Please refer to the R744 Safety Data Sheet:

CIMCO-Specific

- What are the warranty package options for CO2 and Ammonia refrigeration systems with heat recovery?

All CIMCO systems have a 1-year warranty from start-up, covering material, parts, and labor.

- Apart from on-site training by the installer, what certificates or training courses are available for CO2 refrigeration systems in Ontario?

Emerson offers CO2 Training in Brantford, covering the entire system. After the installation is complete, CIMCO provides system training for customers, where we go over the day-to-day maintenance requirements for the system. Bitzer offers training and classes on CO2 compressors. Additionally, we have chiller braze plate glycol training from Alfa Laval.

Related Posts

Guysborough Municipality Raises the Bar With All-in-One CO2 Heating, Refrigeration & AC

Sold-Out IRMA Innovation Day Showcases Next-Gen Ice Arena Technologies

.png?sfvrsn=ad12d922_1)

The Business Case for Replacing Your Refrigerant System

STAY UP TO DATE

Get the latest industry insights and important updates delivered right to your inbox.

|

|