When not in use, the seasonal rink’s refrigeration system provides cooling to the surrounding buildings, projected to deliver future operational savings for University District.

![University District, Calgary - CIMCO Refrigeration [Ice Rink Manufacturers] University District, Calgary - CIMCO Refrigeration [Ice Rink Manufacturers]](https://cdntoromontsites.azureedge.net/cimco-prod-redesign/images/default-source/banners/university-of-calgary---cimco-refrigeration-ice-rink-manufacturers.png?sfvrsn=44a2c722_0)

Overview

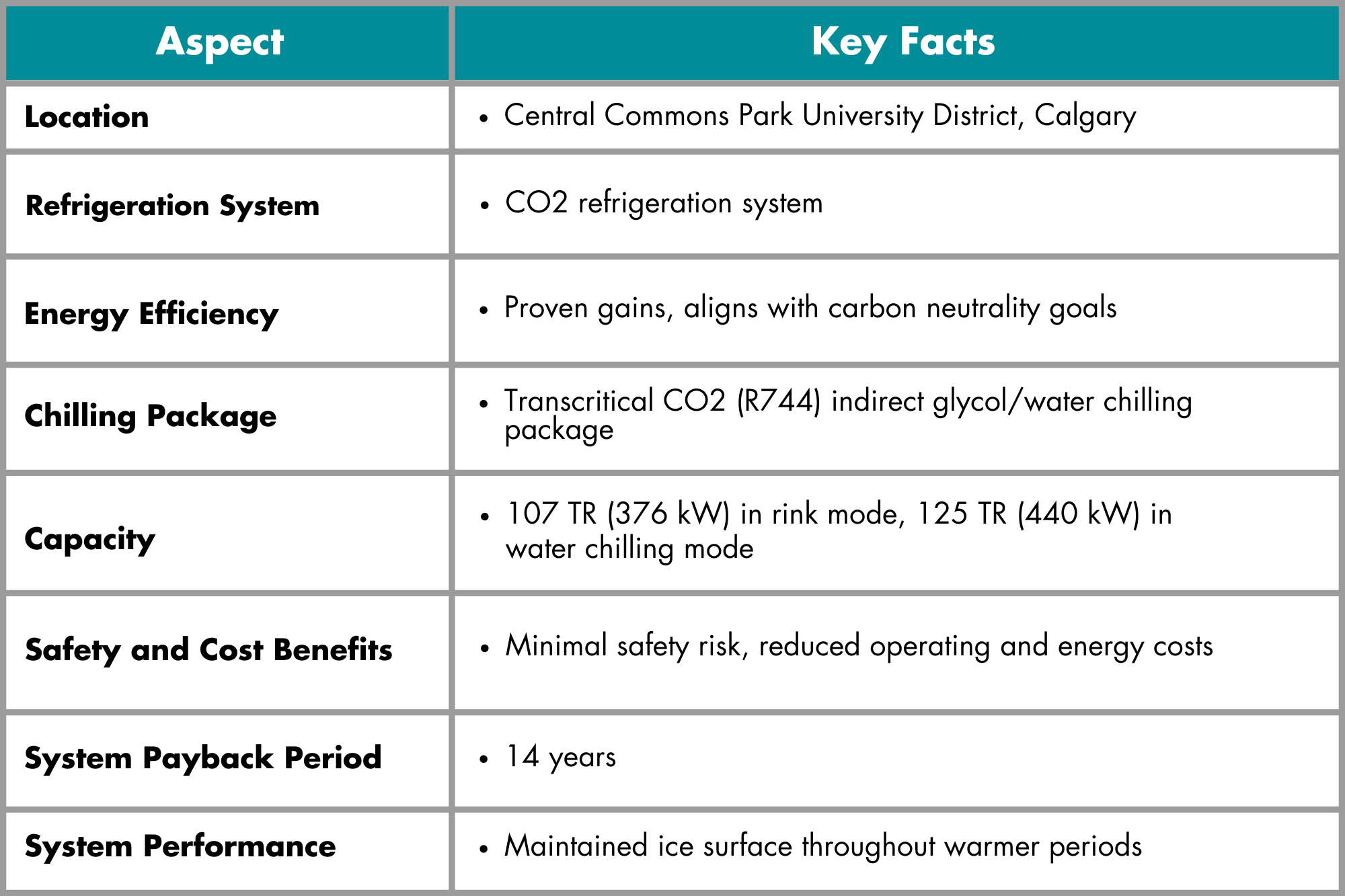

In 2019, plans were unveiled for a new central park in Calgary, called Central Commons Park, in University District, together with two low-rise mixed-use buildings for retail and office space. Although the initial plans did not include an ice arena, these were later modified to include a 40 m x 40 m (131 ft x 131 ft) outdoor skating surface for seasonal operation (November to mid-March).

To further support the sustainability mandate established at the outset of the Master Planned development, and to contribute positively to carbon neutrality goals for the city, a CO2 refrigeration system was proposed for the skating surface. As CO2 is a natural refrigerant with a negligible global warming potential (GWP) that also offers proven energy efficiency gains, it was an obvious choice to meet Calgary’s criteria for reducing its emissions.

The park’s skating surface officially opened in November 2022, although the mix-use buildings have been operational for more than a year prior.

A Clever Solution

After the initial design stage, CIMCO Refrigeration (CIMCO) was called in to advise on a suitable solution for the addition of an outdoor rink. Originally, a separate cooling system was planned for the rink. However, as the skating surface would not be used all year round, it made more sense to incorporate its cooling needs into the chiller system specified for the buildings.

CIMCO worked with the mechanical consultant to integrate the two chiller systems. The initial plan called for two chillers to serve the buildings plus an additional system for the ice surface. However, by integrating the two cooling systems, one chiller could be eliminated – reducing upfront equipment costs.

A transcritical CO2 (R744) indirect glycol/ water chilling package was prefabricated by CIMCO to cool the skating surface. Instead of requiring its own cooling tower to maintain the ice like in a conventional system, the ice surface can now use the building's existing water cooling tower. Avoiding the need for additional equipment results in further cost-saving on the equipment side.

The package comes complete with water-chilling heat exchangers to provide supplemental cooling to the chilled water system when the rink is not in use (April-October). It has a 107 TR (376 kW) capacity in rink mode and 125 TR (440 kW) in water chilling mode.

Why CO2?

CIMCO has had previous experience with the Olympic Oval skating rink at the University of Calgary, using ammonia as a refrigerant for cooling the surface. Given past history and performance metrics, CIMCO found CO2 to be a more suitable solution for the outdoor rink in University District, given the constraints of a below-ground plant room.

“The customer was also swayed on the efficiency and longevity of the CO2 system,” explains Ryan Ferguson, Team Lead Capital Projects, Western Canada at CIMCO. “The CO2 system offers the best long-term solution when considering the safety, operating costs, and risks of refrigerant phase downs.”

"We were impressed with the sustainability benefits of using CO2 as the refrigerant for our new ice rink,” said Donna Marzolf, Director of Construction at the University of Calgary Property Group. “We wanted to create a facility that is not only high-performing but also reflects our commitment to sustainability and reduces our impact on the environment. The use of CO2 refrigeration was a good choice for us, and we're proud to have a sustainable outdoor rink as a result."

The CO2 system has a minimal safety risk, with no flame propagation and low toxicity. It also shows reduced operating and energy costs, especially as the costs of fluorinated refrigerants (f-gases) rise – making leaks a very expensive problem. Not only does CO2 have a lower environmental impact than fluorinated refrigerants, but it also helps reduce energy costs and overall carbon footprint. Plus, the constantly changing policy landscape has ongoingly restricted the use of f-gases, making natural refrigerants like CO2 the only safe bet when selecting a system meant to last multiple decades.

“Using a sustainable refrigerant such as CO2 removes the worry about having to change refrigerants or undergo expensive retrofits just to keep the system operational,” says Ferguson.

Favorable Outlook

The system has been in operation for one full season and although optimizing the controls for both chiller systems was somewhat challenging at first, the system maintained the ice surface throughout the warmer periods and performed well. The efficiency of the system is currently being reviewed and more accurate indicators will be available with a second season to compare to.

"We're optimistic with the CO2 refrigeration system in our new ice rink," says Marzolf. “Over time, the energy efficiency will help us reduce costs and focus on other areas of running the rink. Plus, it aligns with our values around sustainability and environmental responsibility."

Based on CIMCO’s calculations, the system has a payback period of only 14 years. This is because of the lower energy consumption and maintenance costs when compared to an f-gas option such as R449A.

"We're seeing a real shift in the way that ice rinks are being designed and built in Alberta, and the use of CO2-based refrigeration is a big driver for that,” said Ferguson. “With our worsening climate crisis and rising energy costs, it just makes sense to use a system that is more energy-efficient, environmentally friendly, and safe.”

“We're seeing more and more arenas across the province adopting this technology. It's an exciting time for sustainable ice rinks in Alberta, and we're proud to be at the forefront of this trend," Ferguson concluded.

Related Posts

Guysborough Municipality Raises the Bar With All-in-One CO2 Heating, Refrigeration & AC

Sold-Out IRMA Innovation Day Showcases Next-Gen Ice Arena Technologies

.png?sfvrsn=ad12d922_1)

The Business Case for Replacing Your Refrigerant System

STAY UP TO DATE

Get the latest industry insights and important updates delivered right to your inbox.

|

|

![University District, Calgary - CIMCO Refrigeration [Ice Rink Manufacturers] University District, Calgary - CIMCO Refrigeration [Ice Rink Manufacturers]](https://cdntoromontsites.azureedge.net/cimco-prod-redesign/images/default-source/banners/university-of-calgary---cimco-refrigeration-ice-rink-manufacturers415bad179cf96a7ea8b6ff0100a9fc4b.png?sfvrsn=22a2c722_0)