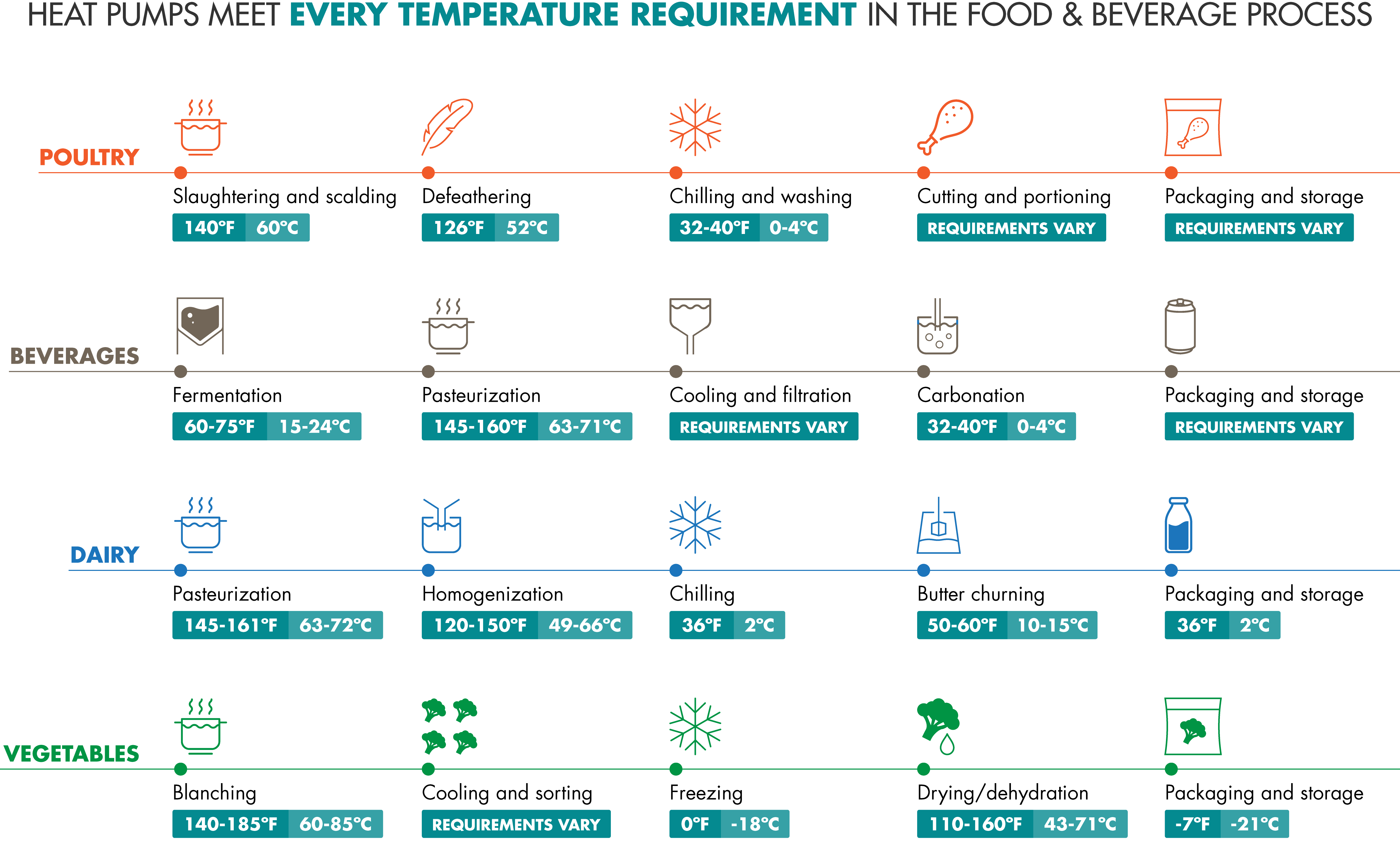

It is an exciting time to work at CIMCO as we shift from refrigeration to using our technical expertise to help with natural solutions with cooling and heating. With today’s technologies we can now start to look at the entire thermal range and provide single solutions that can meet all the temperature requirements with a natural sustainable solution.

Transitioning From Boilers to Heat Pumps: A Greener Path for the Food Sector

Natural gas boilers have long been popular in industrial, food, and beverage applications. However, the escalating prices of natural gas coupled with mounting concerns surrounding energy usage, emissions, and carbon taxes are prompting food and beverage facilities to explore more efficient and cost-effective alternatives.

While production is always a priority within this sector, the changing industrial landscape and interconnectedness of systems and processes allow for a new opportunity. An opportunity to leverage the thermal energy generated from processes and redirect them to operations that need high grade heating and cooling, as and when needed.

Within CIMCO, we are actively collaborating with various industries, including dairy, food processing, breweries, and other applications, to help them lower their greenhouse gas emissions through the adoption of heat pumps. These sectors have traditionally been significant contributors to carbon emissions due to their extensive heating requirements. By partnering with CIMCO, these industries can leverage the expertise and experience of a leading provider of industrial cooling and heat transfer solutions to implement sustainable and efficient thermal solutions.

Dairy Industry

The dairy industry is a prime candidate for the adoption of industrial heat pumps. Milk processing requires precise temperature control throughout various stages, including pasteurization, sterilization, and drying. By utilizing heat pumps, dairy processors can efficiently generate the required heat at lower temperatures, reducing both energy consumption and associated greenhouse gas emissions. Processes such as pasteurization need high temperatures as high as up to 161 degrees Fahrenheit and heat pumps designed by CIMCO can achieve these temperatures, even as high as 180 degrees Fahrenheit.

We are actively working with dairy industry stakeholders to identify opportunities for integrating heat pumps into their processes, contributing to a more sustainable dairy production chain.

Food Processing

In the food processing sector, heat pumps serve as a valuable addition to refrigeration systems. They are particularly beneficial in environments where heat-intensive operations such as cooking, drying, and sterilization is common. Their ability to efficiently extract and upgrade heat from the environment makes them highly energy-efficient solutions. According to a study by the International Energy Agency (IEA), industrial heat pumps have the potential to reduce energy consumption for process heating by up to 50% compared to conventional heating methods. By utilizing waste heat and operating efficiently, heat pumps further contribute to carbon emissions reduction, aligning with sustainability goals.

Breweries

Breweries, renowned for their energy-intensive operations encompassing mashing, boiling, and fermentation, stand to reap significant advantages from the integration of heat pumps. By harnessing waste heat generated during brewing processes and leveraging heat pumps, breweries can efficiently capture and repurpose this thermal energy. This reclaimed heat can then be utilized for diverse heating requirements, ranging from water heating for brewing purposes to space heating within brewery facilities.

In fact, breweries typically produce large quantities of waste heat during the brewing process. For instance, mashing involves steeping grains in hot water to convert starches into fermentable sugars, which generates considerable heat. Similarly, the boiling stage requires heating the wort to sterilize it and extract hop flavors, further contributing to heat generation. Additionally, fermentation involves maintaining specific temperatures to facilitate yeast activity, resulting in additional thermal output.

By incorporating heat pumps into their operations, breweries can not only reduce their reliance on traditional heating methods but also minimize energy waste by efficiently repurposing waste heat. This not only leads to cost savings but also enhances the sustainability of brewery operations, aligning with environmental objectives.

Other Applications

Beyond dairy, food processing, and breweries, CIMCO has been actively collaborating with diverse sectors to unlock the potential of industrial heat pumps in attaining the desired temperatures, lowering emissions and operational costs. These sectors encompass pharmaceuticals, chemical processing, manufacturing, and beyond. Recognizing the varying heating demands and operational challenges within each industry, CIMCO engages closely with stakeholders to develop tailored heat pump solutions.

In pharmaceuticals, for instance, stringent temperature control is essential for maintaining product integrity and safety during manufacturing processes. Similarly, in chemical processing, where high temperatures are often required for reactions and product synthesis, heat pumps offer a sustainable alternative to traditional heating methods. In manufacturing, Whether it's providing heat for material processing, space heating, or equipment sterilization, heat pumps offer versatile solutions tailored to the specific needs of each manufacturing facility.

While the upfront cost of installing a heat pump system can be higher than traditional heating and cooling systems, the long-term savings in energy costs often outweigh this initial investment.

Commitment to Sustainability

CIMCO is committed to designing heat pumps customized to specific processes and operational requirements, prioritizing factors crucial to each industry's success. Our tailored solutions ensure optimal performance, efficiency, and sustainability, empowering industries to achieve their goals while minimizing environmental impact.

Contributors:

RYAN FERGUSON - TEAM LEAD CAPITAL PROJECTS, WESTERN CANADA

Ryan has held various progressive roles within the CIMCO organization over the last 13 years. He started in the project engineering group where he quickly gained the technical aptitude and experience in the design and installation of many types of direct and indirect refrigeration systems in both the industrial and recreation markets. He quickly transitioned into the project sales group as a technical resource and worked developing customer relationships and custom design build proposals. He then transitioned to his current role as the capital project team lead for western Canada supporting his colleagues with lead generation, system design, estimating and proposals to meet customer requirements with improved efficiency, reliability and safety in mind. He has a passion for developing sustainable solutions that offer the lowest cost of ownership over the life of a system.

e: rferguson@toromont.com

DAVID FAUSER - DIRECTOR OF SALES

David has been with the CIMCO for more than 20 years. During that time, he has been involved in hundreds of new plant designs and retrofits throughout North America. David has a passion for ice sports and sustainability, and was instrumental in CIMCO’s decision to drop recreational ice rink packages that use refrigerants with high global warming potential from its lineup, because of their climate impact. He is a strong voice on environmental issues and legislation, and is a thought leader in the industry. He believes that there is a solid business case to incorporating net-zero and net-zero-over-time strategies to today’s industries.

e: dfauser@toromont.com

Related Posts

Advanced Refrigeration Management: The CIMCO IQ Advantage

CIMCO's Thermal Force One: The Smart Choice for Forward-Thinking Ice Rink Operators

Thermal Hub: A Complete Solution for High-Temperature Water, Chilled Water, and Ice Storage

STAY UP TO DATE

Get the latest industry insights and important updates delivered right to your inbox.

|

|